Engines

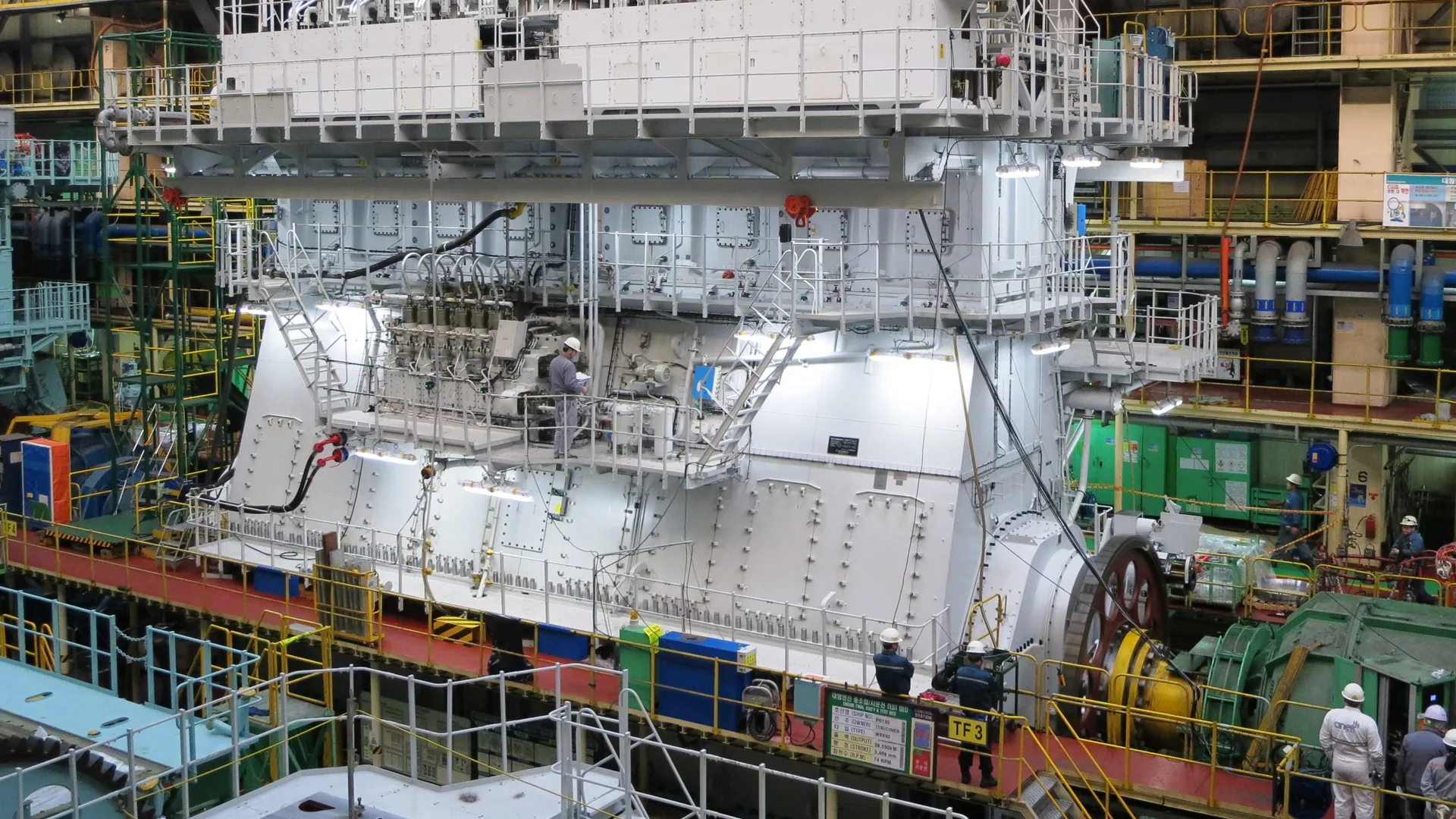

Somas’ valves have been used for many decades to control the exhaust flow after combustion in large engines in both marine and on-shore installations. Current requirements when it comes to fuel efficiency and environmental awareness have increased the need for accurate control as well as the option to shut off exhaust flows completely.

Somas’ exhaust gas valves

Exhaust gas valves are designed to handle exhaust gases from engines and are becoming increasingly sought after on the market. This suits us perfectly, because we have a wide range of exhaust valves.

The butterfly valve is the most suitable type of valve for handling exhaust gases. Somas’ unique valve disc and flexible metal seat result in a highly efficient control element for exhaust gases. The valves must be able to handle difficult temperature cycles, soot and corrosive substances in the exhaust gas flow, as well as powerful vibrations. In order to minimise downtime for maintenance and repair work, the design of bearing bushings and shaft seals is also a specific requirement for exhaust gas installations. Somas’ valves are designed with an extended shaft, making it possible to install the actuator away from the valve. The actuator and its accessories are more sensitive to high temperatures than the valve, and so it is important to move these parts as far away from the hot valve as possible.

The actuators can be set in fail-safe mode, and pneumatic actuators with accessories are normally used to achieve the desired functionality. Electric actuators can also be used, although this is much less common.

Product information exhaust gas valves

- Butterfly valve dimensions DN 80-DN 1200, up to DN 1600 on request

- Ball segment valve dimensions DN 25-DN 65

- Pressure classes PN 10-PN 50

- Butterfly valves with a metal seat and ball segment valves with a HiCo seat offer good tightness in accordance with current industry and application requirements

- The torque carries over from the actuator to the valve without delay, and the same goes for the transfer between actuators and positioners

- Service-friendly design where the seats of both butterfly valves and ball segment valves can be replaced without the need to dismantle the actuator. In addition, the valves do not need to be completely disassembled to be repaired

- Standard valve up to 550°C

- High temperature valve up to 700°C

When reliability is important

Somas’ valves have been developed to be suitable in a wide range of industries. Our aim is to ensure that the choice of materials and the design meet the specific requirements stipulated in your particular industry.